Furniture production: an inside look

Content:

- Features of furniture production

- Furniture production technology

- Requirements for furniture production

- Types of furniture production

- Equipment for furniture production

Furniture companies specialize in the manufacture of furniture for premises for various purposes, including residential, public and office. A large part of this industry is occupied by home furnishings. Both large enterprises and small businesses are engaged in furniture production. Some of them have launched the production of cabinet products, others produce upholstered furniture, but the operating principle of their furniture production is identical.

Features of furniture production

There are certain stages in the manufacture of furniture products, but each company may have its own technological features. This is primarily due to the type of organization of furniture production.

Some enterprises provide a full production cycle, which begins with the manufacture of materials (wood panels and panels) and ends with the release of finished products.

There are manufacturers who purchase ready-made materials, and then cut and assemble the products. Another option for furniture enterprises involves only assembling furniture from cut materials. They are essentially an assembly shop.

Furniture production can be fully automated or use manual labor. The second option is more typical for small businesses. Large enterprises often use automated equipment, which allows them to achieve high accuracy, reduce the number of defects and reduce labor costs.

Furniture production technology

The standard furniture manufacturing process includes:

- Sketch development. At this stage, the design of future furniture is developed, as well as design documentation, which includes drawings of parts, cutting maps, a list of materials and accessories necessary for the manufacture of the model. Any mistakes at this stage may result in the furniture being impossible to assemble or inconvenient to use.

- Uncover. Before cutting wood materials, they are dried to subsequently avoid deformation and warping. After this, blanks of the desired size and shape are made.

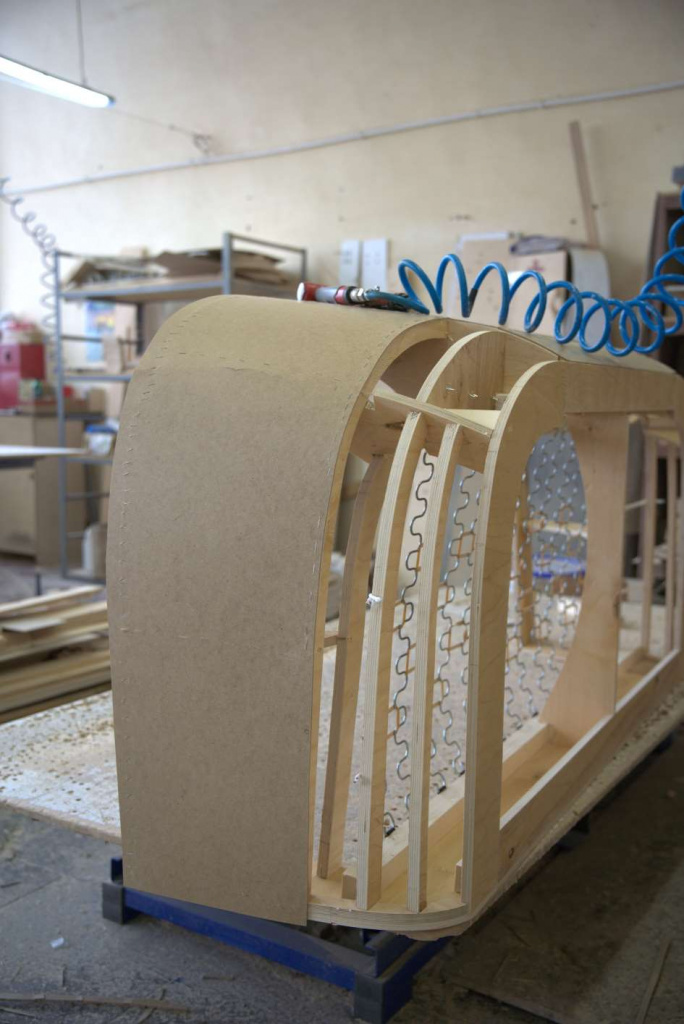

- Creation of assembly parts. To produce curved workpieces, a technology such as bending is used. In addition, mechanical processing may include jointing, planing and facing. As a result of these operations, a workpiece of the desired shape is obtained. Then follow the operations that will bring the workpiece into compliance with the drawing - cutting tenons, drilling, milling.

- Assembly. Structural elements of furniture are assembled from individual parts, for example, frames, boxes, panels, etc., and then everything is combined into a single whole, if the furniture does not require assembly after purchase.

This is a simplified description of the technological process, since in the manufacture of cabinet furniture the stages of cladding and applying a protective coating may be provided, and in the production of upholstered furniture - cutting upholstery fabric, creating a spring block, etc.

Requirements for furniture production

Technical aspects of furniture production are regulated by GOST, which establishes requirements for the materials used, the quality of furniture manufacturing, rules for its inspection, and also provides recommendations for labeling, packaging, transportation and storage. In addition, a number of requirements are imposed on products:

- Functional. Furniture must correspond to the intended purpose and operating conditions. Therefore, during development, the most rational dimensions and other characteristics that may affect the level of comfort during use must be calculated.

- Ergonomic. These requirements consider furniture in the context of organizing space, convenient storage of objects, optimal location of the human body in terms of anatomy, limiting the influence of harmful influences, etc.

- Constructive. They are installed to improve furniture designs, including their stability and strength, optimal connections and operational reliability. The simplicity of the design of furniture and its individual elements affects the performance properties, and the strength, service life, efficiency and weight depend on the materials used.

Types of furniture production

Furniture companies can have different sizes and organize work in different ways. There are three main types of production organization:

- To order. When manufacturing furniture to order, the production volume is planned based on received orders for products. Each product or a small number of them is manufactured after receiving an order; the development of sketches can be carried out on an individual basis, taking into account the needs of the customer. The main client, as a rule, is the final buyer who purchases furniture for his own use, office equipment or cafe. With such a business process, the main difficulty is meeting the order production deadlines.

- Serial. This variant of production organization is characterized by the production of furniture in batches. Depending on the number of products in a series, production can be classified as small-, medium- and large-scale. The client of a serial manufacturer is a wholesaler-dealer or showroom, but some manufacturing companies provide for the sale of furniture directly to the end consumer.

- Mass. In this case, the manufacturer produces the same range of furniture over a long period of time. The mass type is economically the most profitable, so the cost of production is usually low. The disadvantages include “faceless” furniture devoid of individuality.

Equipment for furniture production

The main factors for the profitability of furniture production include production equipment. The basic list includes:

- Edge banding machine. It is necessary for final processing of the end surfaces of panels made of various wood materials.

- Format-cutting machine. Allows you to perform many tasks from cutting boards to size to cutting large sheets of a wide variety of materials. There are several types of such machines, so you can choose equipment that corresponds to the technology of a particular production.

- Reismus. This is planing equipment that is designed for making boards and processing wood products. It helps eliminate existing defects on the surface and give them the desired shape.

- Four-sided type machine. It combines several functions: cutting material to length, creating the desired profile, removing chips, vertical cutting.

- Drilling and additive installations. Necessary for creating holes in workpieces.

- Sewing equipment. Special sewing machines for working with dense fabrics are used in the production of upholstered furniture.

The Garda Decor company is one of the examples of modern furniture production, which specializes in the production of exclusive designer furniture. More information about the organization of the production process can be found at the link https://gardadecor.ae/proizvodstvo/

- Furniture for restaurants, cafes and bars: what is needed, requirements, features

- Apartment in contemporary style: design features

- How to open a furniture store from scratch and how much money you need for this

- The specific smell of new furniture: the reasons for its appearance and inexpensive ways to combat it

- How to become an interior designer yourself: what you need for this and where to start

- Outdoor furniture: recommendations from experts on choosing comfortable and practical furniture

- Checklist for choosing a furniture manufacturer: the most important criteria

- Selecting a palette for the interior: trends for 2022

- Bar stools: types and detailed guide to choosing